This event’s focus is not so much on delivering a finished game as delivering a platform for learning micropython.

The board consists of a SeedStudio/Xiao RPI2040 which has just enough pins for this project. It also has a built-in WS2812 RGB Led along with additional LED’s on board.

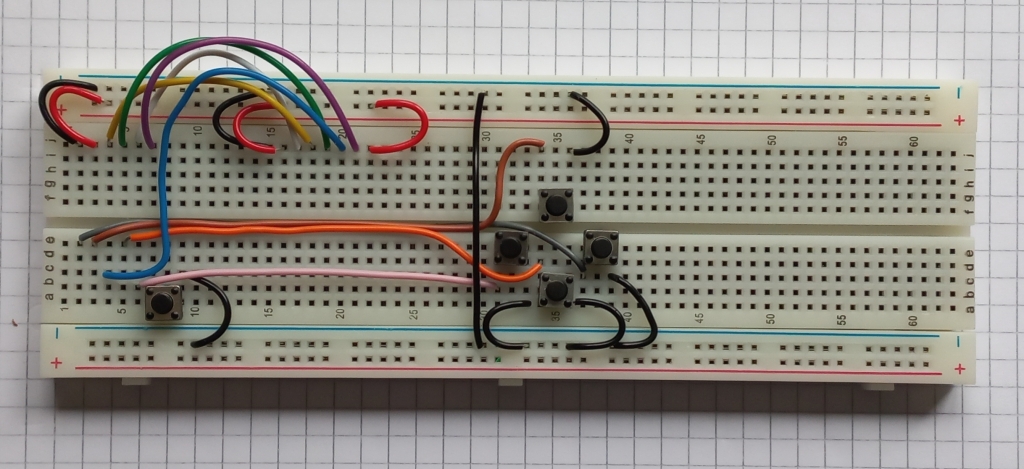

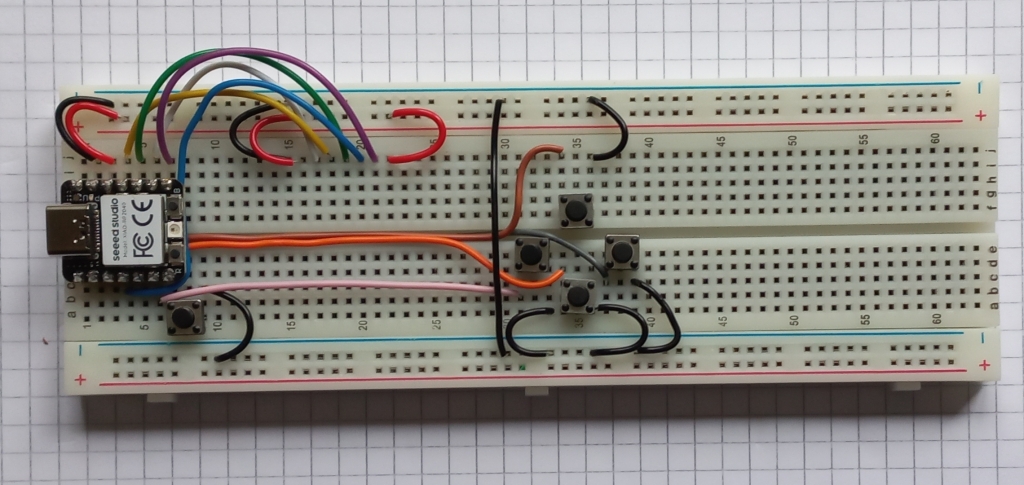

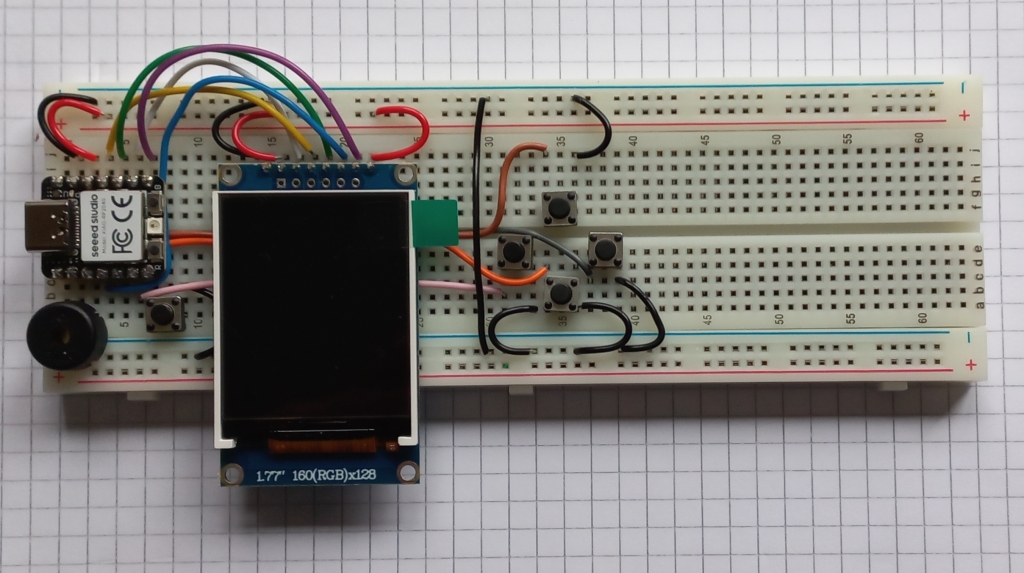

A set of construction images is shown below. Be careful to place the wires and components exactly as shown. The breadboard has rows labelled a to j and columents 1 to 63 which may help when inserting components. If you would like to know more about breadboards this video may help:

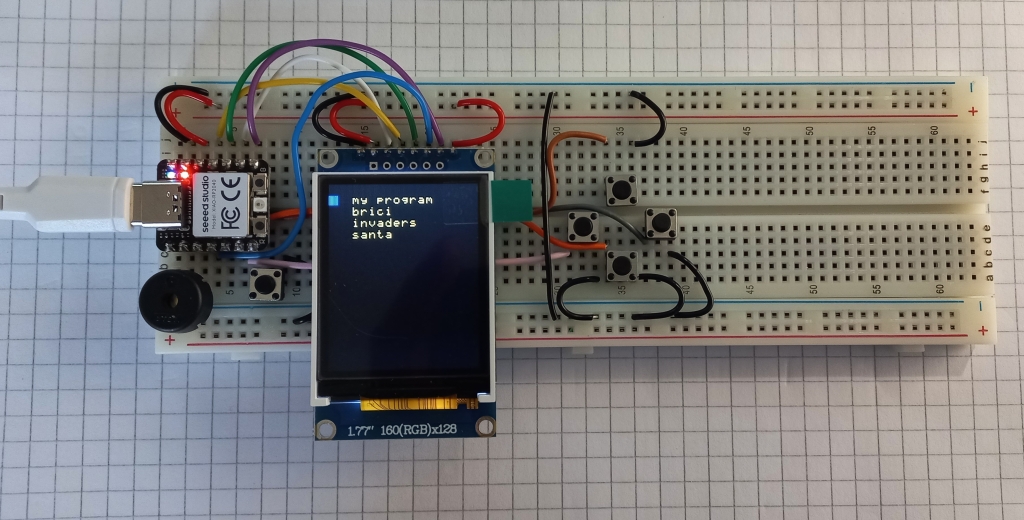

Construction image gallery

The following three images show the placement of the display wires and grounds on this board

The image below shows the placement of the gamepad wiring. Be sure to run the wires in the slot as shown. The left-most button is equivalent to the A button on a game controller. Its left pin lines up with a pin on the microcontroller development board so no wire is needed for it (apart from ground).

The long black and blue wires are shown below. Be careful to leave space for the microcontroller board when routing the blue wire.

The microcontroller boards is placed as shown. It fits in to the left-most holes of the breadboard.

The buzzer placement is shown below. One pin goes into the ground track of the breadboard, the other wire goes to the leftmost column of the breadboard just below the microcontroller board.

Finally, fit the display as shown below. Be careful to line up the pins with the wires as shown.

Programming

Our game console is programmed in Micropython which is best accessed using the Thonny development environment. There are three ready-made games which will hopefully help your learning of micropython and the hardware on our board. There is also a place for you to create your own game. When the board starts you are presented with a menu which allows you select from these (press A to select). There are lots of micropython and python learning resources on the Internet. The basics of Python can be studied here: https://www.w3schools.com/python/. Micropython tutorials tend to be board specific. A tutorial for our XIAO board can be found here: https://wiki.seeedstudio.com/XIAO-RP2040-with-MicroPython/. Board documentation is available here (check the rpi2040 chapter): https://files.seeedstudio.com/wiki/XIAO/Seeed-Studio-XIAO-Series-SOM-Datasheet.pdf

The code you will use in this exercise includes additionaly libraries to manage our specific hardware. This hardware includes the display, the buzzer, the various buttons and the onboard RGB led. Here is a list of the functions within these libraries.

Functions that control the display

putPixel(x,y,colour): lights up a display pixel with the specified location and colour

drawLine(x0,y0,x1,y1,colour): x0,y0 = start point, x1,y1 = end point

fillRectangle(x1,y1,w,h,colour): x1,y1 = top left corner, w=width, h=height

drawRectangle(x1,y1,w,h,Colour): x1,y1 = top left corner, w=width, h=height

clear(): clear the screen to black

putImage(x,y,w,h,img,horiz,vert): put image at x,y. Width is w, height is h. Image data is in img and h,v specify whether image is inverted in horizontal or vertical axes

setOrientation(h,v): set display orientation (0,0) = default

print(text, x, y, forecolour, backcolour): print text at x,y with foreground and background colours

drawCircle(x0,y0,radius,colour): circle with

fillCircle(x0,y0,radius,colour):

RGBToWord(r,g,b): convert 8 bit red, green and blue values to a 16 bit colour value

Functions that use the gamepad buttons

leftPressed(): returns 1 if the left button was pressed

rightPressed(): returns 1 if the right button was pressed

downPressed(): returns 1 if the down button was pressed

upPressed(): returns 1 if the up button was pressed

aPressed(): returns 1 if the A button was pressed

buttonPressed(): returns a bit patten for the various buttons (0 if nothing pressed)

Functions that manage sound

sound.tune.append() : append a note to the sound array

sound.note(frequency,duration,pause)

Sprite functions

sprite(x,y,w,h,image,display): creates at sprite with the initial position x,y. Bounding rectangle height=h,width=w

show(): show the sprite on screen

hide(): hide the sprite

move(newx, newy): move the sprite (erase at the previous location)

move_no_erase(newx, newy): move the sprite (don’t at the previous location)

setOrientation(horiz, vert): set sprite horizontal and vertical orientation (default 0,0)

isOverlapping(sprite2): do this sprite overlap another?

RGB Led support

set_colour(self,red,green,blue): light up the onboard LED with the particular color

Once you have finished building the board (and playing the games) we will explore how you might write your own game. Starter code for this event is available below: